Sustainably produced concrete mixtures from mineral residues and waste supplies may partially change Portland cement-based concrete sooner or later, particularly in software environments susceptible to corrosion resembling sewage methods, biowaste vegetation or tunnel drainage methods. Cyrill Grengg from the Institute of Utilized Geosciences at Graz College of Know-how (TU Graz) argues that it isn’t solely an achievable objective, but additionally makes financial and ecological sense.

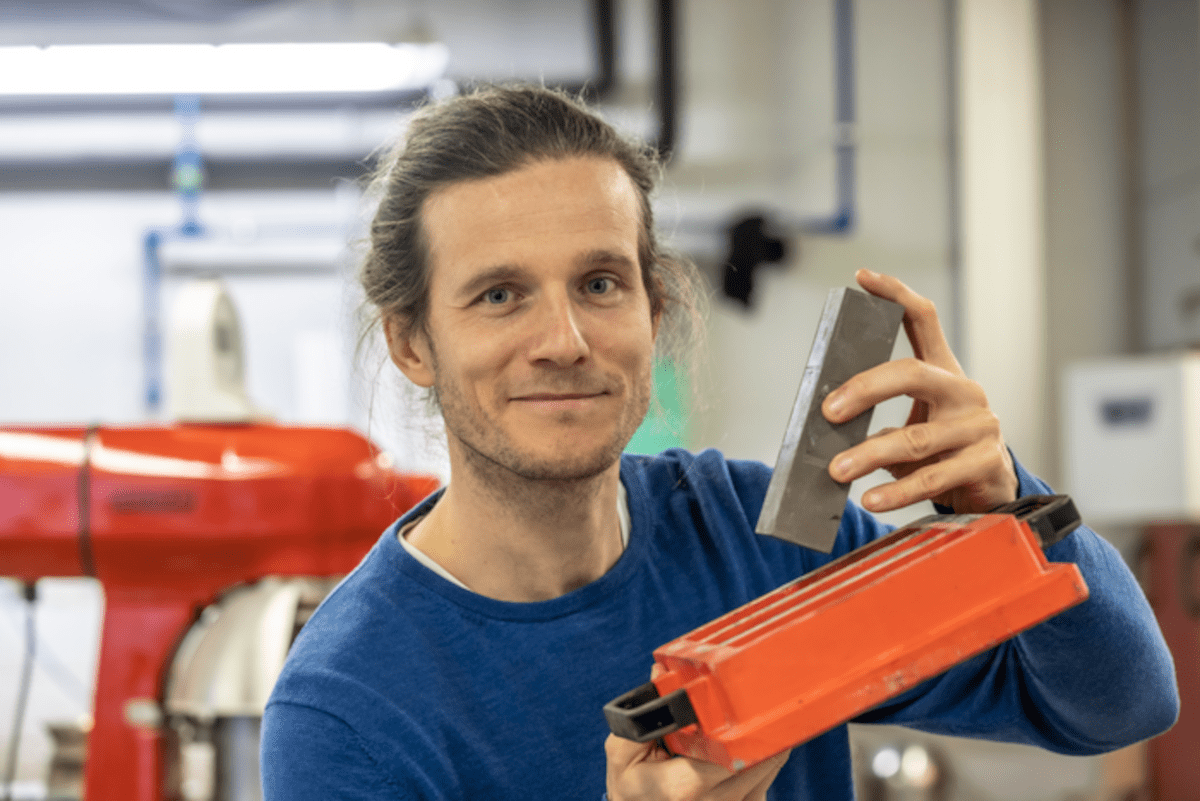

He heads the Christian Doppler Laboratory for waste-based geopolymer development supplies within the CO2-neutral round financial system, which formally opened on 8 March, and has eight company companions* concerned within the undertaking, who all seemingly see potential in the usage of constructing rubble, slag, metallurgical gravel, mineral wool or ash to make extra environmentally pleasant and resistant concrete.

The undertaking is working to a seven-year timeline of analysis – along side the taking part corporations – with funding from, amongst others, Austria’s Federal Ministry of Labour and Financial Affairs (BMAW). “The know-how researched right here may be the premise for a lot of different improvements,” commented Minister of Labour and Financial Affairs Martin Kocher.

Much less consumption of cement and sources and fewer corrosion

Inorganic industrial secondary uncooked supplies, resembling slag and ash, in addition to residual supplies, resembling mineral wool and clay-rich demolition supplies, are processed within the CD lab and mixed with carbon-rich waste supplies, resembling (waste) oils, biomass residues or natural fibres, relying on demand and supposed use. The ensuing geopolymer is an alternative choice to typical Portland cement-based concrete. It gives comparable materials properties, has higher resistance to many sorts of corrosion and results in much less consumption of sources by means of recycling of beforehand landfilled residual and waste supplies.

“Chemically, the geopolymer is one thing utterly totally different from Portland cement, however the bodily properties are very comparable and even higher in some instances,” says Grengg, who extolls the potential of geopolymers, particularly of their a lot larger resistance to (bio)chemical corrosion. Portland cement is by far probably the most broadly used binder in trendy development. Nevertheless, it’s prone to corrosion from wind, climate and different environmental influences, resembling (bio-)chemically aggressive wastewater from sewage methods and sewage remedy vegetation. This results in security issues and excessive bills for the upkeep of constructions. Worldwide, prices attributable to corrosion are estimated at 2.5 trillion US {dollars} (or approx. 3.4 % of the worldwide gross home product), giant shares of which relate to concrete as a constructing materials.

From landfill to recycling financial system

On the similar time, the manufacturing of constructing supplies is answerable for about 9 % of all greenhouse gasoline emissions generated worldwide. And the present dealing with of residual and waste supplies, for instance from development initiatives, nonetheless has nice potential by way of recyclability. Yearly, 54 million tonnes of mineral waste are generated in Austria, which is 76 % of the full waste quantity. Of this, virtually 60 % is landfilled, ensuing within the lack of helpful sources and enormous areas of land to landfill. “At present, giant quantities of the residues and wastes used within the CD lab are landfilled, and solely a small half is recycled. We wish to take these supplies away from landfills and combine them right into a CO2-neutral recycling financial system,” says Grengg.

* The company companions within the undertaking are Voestalpine Stahl Donawitz GmbH, Stahl- und Walzwerk Marienhütte GmbH, brantner inexperienced options GmbH, Initiative Ziegel, Analysis Affiliation of the Stone and Ceramic Business, CharLine GmbH, Kirchdorfer Fertigteilholding GmbH, MM-Kanal- Rohr- Sanierung GmbH and the Group of Styrian Wastewater Disposal Firms (together with Linz AG and AWV Wiener Neustadt).